- Products Details

Quick Details

-

Brand Name: Shineheat

Model Number: SHW

Place of Origin: CHINA

Packaging & Delivery

- Packaging Details: PLYWOOD

- Delivery Detail: 25 DAYS

Specifications

SHINEHEAT is specialize in the production of stainless steel equipment, it's machinery facilities including sawing, bending and trimming, shearing and cutting, welding, pickling and passivating and glass pearl blasting.

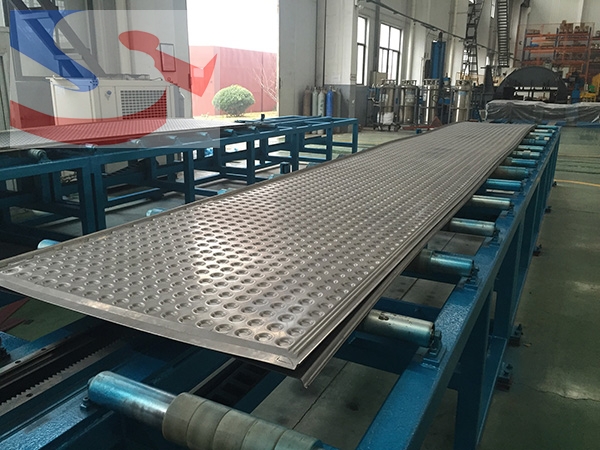

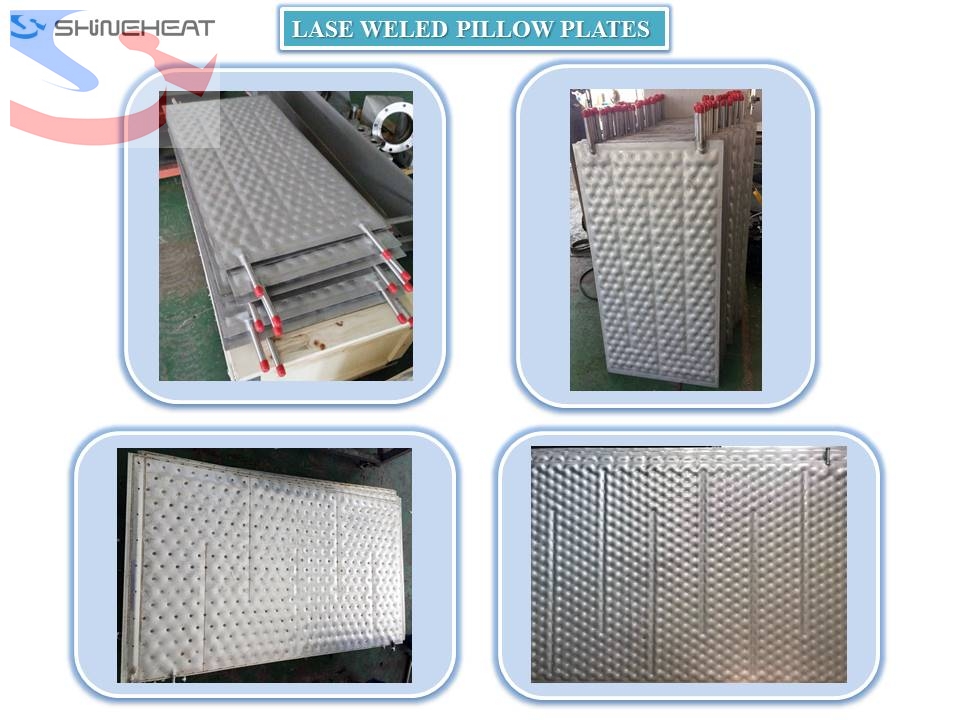

Laser Welded Pillow Plate:

Heat exchange pillow plate is machined by full automatic laser welding and forming process. Its unique pillow structure makes fluid into optimum turbulence state to achieve high efficient heat exchange. It also boasts various advantages such as dust proof, high temperature and high pressure resistance and easy cleaning, etc.

The Application for Welded Pillow Plate:

Thermal Elements for Bulk and Solids Heat Exchanger

Thermal Elements for Bulk and Solids Heat Exchanger

The bulk solids heat exchangers have a modular product structure, based on first-class pillow plates. These pillow plates are assembled into one or more plate package, between which the bulk solids, to be cooled or heated, flow. These are heated or cooled to the temperature required by the heat-exchanging medium – primarily water, steam or thermal oils – which flow through the channels of the pillow plates.

Bulk solids are distributed over the pillow plates in a hopper, in which a level indicator is used to measure the fill level and flow rate too. To ensure that the bulk solids are heated to a uniform temperature, an even flow must be achieved across the entire surface of the heat exchanger. This so-called mass flow is created by means of an outlet designed especially for this purpose. As a result, every particle of the bulk solids flows through the heat exchanger at the same rate and are consequently in contact with the pillow plates for the same length of time. A temperature sensor in the product outlet ensures that the bulk solids are at the temperature required as they leave the heat exchanger.

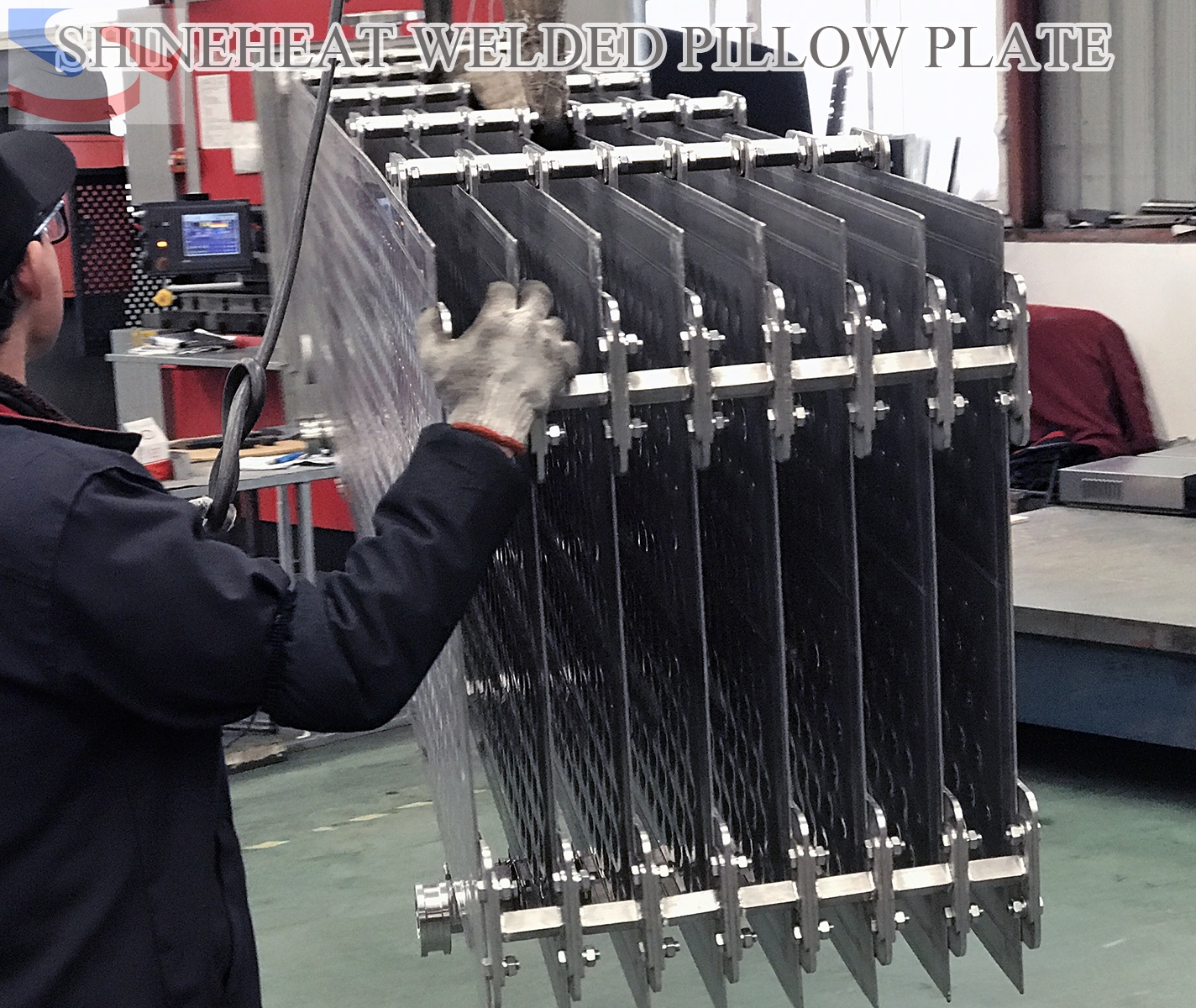

Special Struture Design for Bolts Connection

For better service and maintanence for pillow plates package, we connect each pillow plate by Bolts method instead of Welding.

In future operating, any pillow plate of package meet problem in leakage, then it could be easier to remove it from package.

It will assemble in postion very well in instantly after repaired.

It also realise the pillow plate expansion and reduce in flexible way subject to working capacity changing.

Pillow Plate Vessel & Tank

Performed as to Cooling Jacket or Heating Jacket, Pillow Plate could be rolled into specific specificiations and forming into different Vessel and Tank for various Heating and Cooling applications.

The Typical Applications

• Beverage processing vessel

• Fermenters, beer vessel, cooking vessel

• Dairy processing vessel

• Pharmaceutical and processing vessel

• Storage tank

• Reactor vessel

The Main Parameters for Welded Pillow Plates

* Working pressure can go up to > 100 bar

* Jacket thickness varying from 0,8 to > 2,5 mm,

* Vessel thickness from 2,0 to > 20 mm.

* Standard: ASME, AD2000, EN13445 and PED.

Scale: 51 - 100 People

Country/Region: China (Mainland)/Asia

Established: 2016